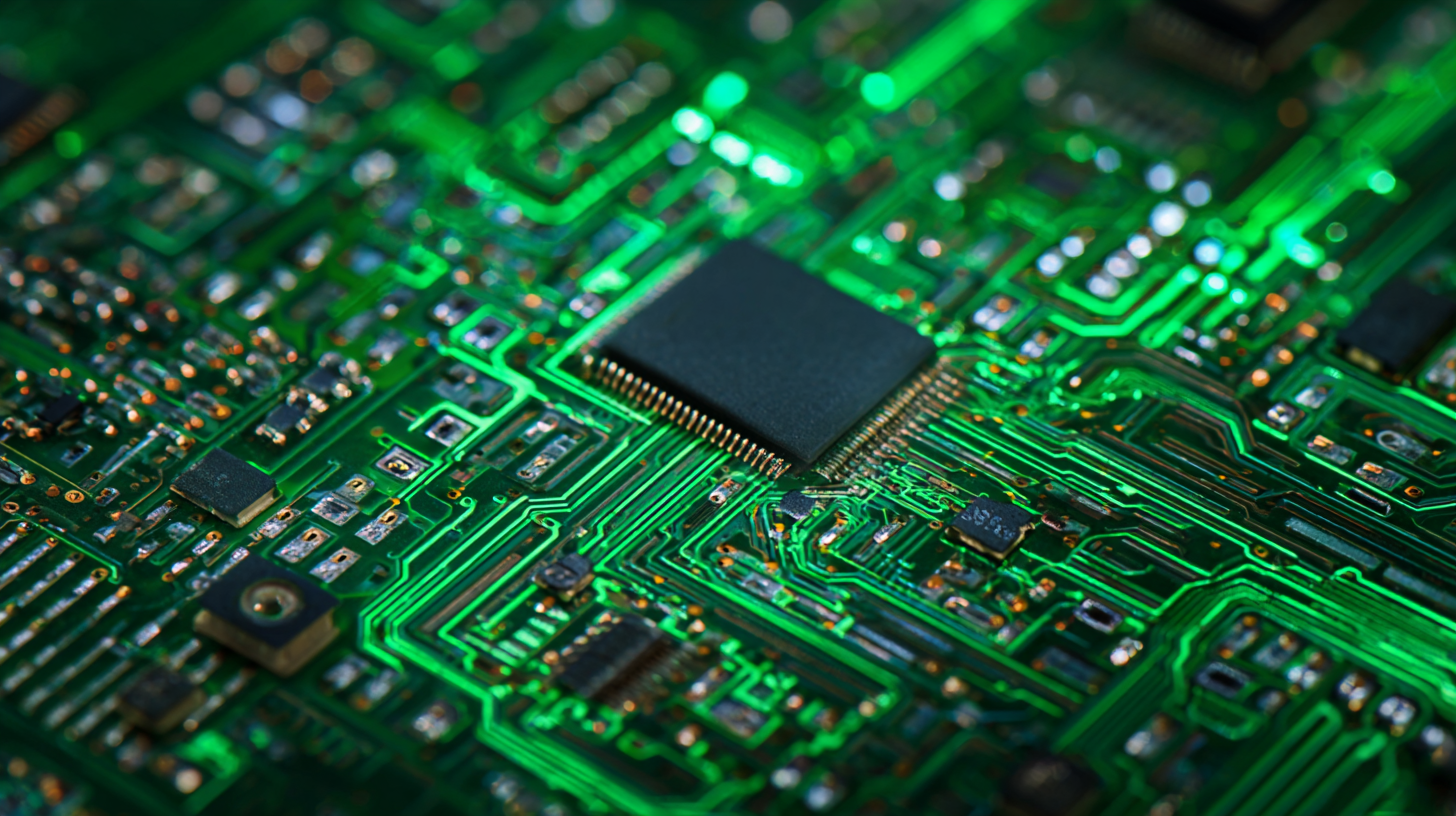

In today's fast-paced electronics industry, ensuring quality and efficiency in the PCB process is paramount for global buyers. According to a recent report by IPC, nearly 70% of all manufacturers face challenges in maintaining quality standards while keeping production costs low. As the demand for advanced electronic devices continues to rise, the complexity of PCB design and manufacturing also escalates, with a projected 6% annual growth rate in the PCB market over the next five years. This highlights the importance of a comprehensive checklist for optimizing the PCB process, enabling buyers to navigate potential pitfalls and enhance product reliability. In this blog, we will explore an ultimate PCB process checklist that empowers global purchasers to streamline their operations and achieve superior results in their electronic assembly projects.

Ensuring quality in PCB manufacturing is essential for global buyers aiming for efficiency and reliability. The manufacturing process includes critical steps that affect the overall quality of printed circuit boards. Research from the IPC International Association of Electronics Industries indicates that nearly 60% of PCB failures originate from design and manufacturing defects, which underscores the need for a stringent quality assurance process.

First, meticulous design validation is paramount. Adopting advanced design-for-manufacturability (DFM) principles can minimize errors before production begins. Data from market analysts shows that implementing DFM practices can reduce production costs by up to 15%, while increasing throughput. Subsequently, during the fabrication stage, rigorous inspections such as automated optical inspection (AOI) and x-ray verification catch defects early, enhancing reliability. According to a recent study, PCB manufacturers employing AOI experienced a 40% reduction in defects, further supporting the importance of these quality control measures.

First, meticulous design validation is paramount. Adopting advanced design-for-manufacturability (DFM) principles can minimize errors before production begins. Data from market analysts shows that implementing DFM practices can reduce production costs by up to 15%, while increasing throughput. Subsequently, during the fabrication stage, rigorous inspections such as automated optical inspection (AOI) and x-ray verification catch defects early, enhancing reliability. According to a recent study, PCB manufacturers employing AOI experienced a 40% reduction in defects, further supporting the importance of these quality control measures.

Finally, the assembly process requires careful attention, with strategies like parallel testing and real-time monitoring being implemented to ensure that components meet strict performance standards. A significant report from the Electronics Industry Citizenship Coalition (EICC) highlights that organizations with robust quality assurance protocols report a 30% decrease in product recalls. By adhering to these essential manufacturing steps, global buyers can significantly strengthen the quality of their PCB products, ultimately leading to higher customer satisfaction and loyalty.

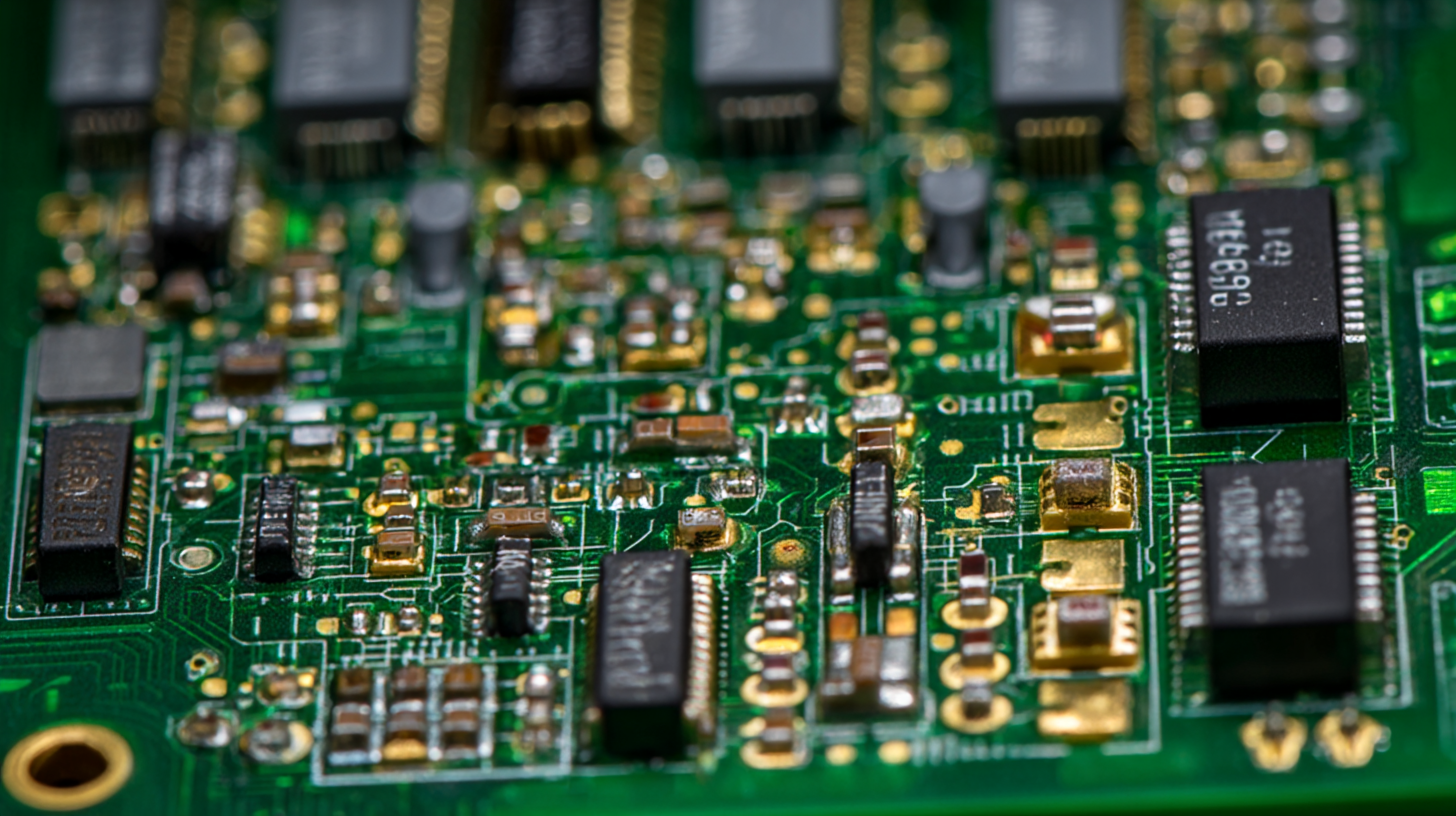

When sourcing PCB (Printed Circuit Board) suppliers, global buyers must consider key factors that ensure both quality and efficiency. According to a report from IPC, the global electronic manufacturing services (EMS) market is expected to reach $500 billion by 2025, indicating a surge in demand for high-quality PCBs. Buyers should focus on supplier certifications, such as ISO 9001 and IPC-6012, as these standards reflect a commitment to quality management and robust manufacturing practices. A supplier’s track record with certifications can serve as an indicator of their reliability in maintaining strict quality control.

Furthermore, the evaluation of a supplier’s technological capabilities is crucial. Research from Technavio suggests that advancements in PCB technology, including the adoption of automated assembly processes, can improve production efficiency by up to 30%. Buyers should assess whether potential suppliers have invested in modern machinery and design software, as this can significantly reduce lead times and errors in the production process.

Overall, emphasizing these factors during supplier selection can lead to enhanced product quality and operational efficiency, ultimately benefiting the buyer’s bottom line in the competitive electronics market.

When sourcing printed circuit boards (PCBs) globally, assessing vendor credentials and experience is crucial to ensuring product quality and manufacturing efficiency. According to a recent industry report, nearly 60% of manufacturing defects can be traced back to poor vendor selection. This statistic highlights the need for buyers to conduct thorough evaluations of potential vendors.

To start, consider checking the vendor’s certifications. A reputable PCB manufacturer should have certifications such as ISO 9001 for quality management systems and IPC standards for assembly and design processes. These certifications serve as a benchmark for manufacturers, ensuring they adhere to quality protocols that mitigate risks of errors in production.

Additionally, examine the vendor's industry experience and client portfolio. An established vendor with experience relevant to your specific application can significantly impact the reliability of your PCB. For instance, a vendor with a track record in medical device manufacturing will be more adept at meeting stringent regulatory standards. Engaging with their previous clients can also provide insight into their operational capabilities and customer service. These evaluations will contribute to making informed decisions that enhance product quality and operational efficiency.

This chart represents the evaluation criteria for PCB vendors focusing on quality and efficiency. The scores indicate how well potential vendors perform in areas such as quality assurance, delivery timeliness, technical support, cost efficiency, and industry experience.

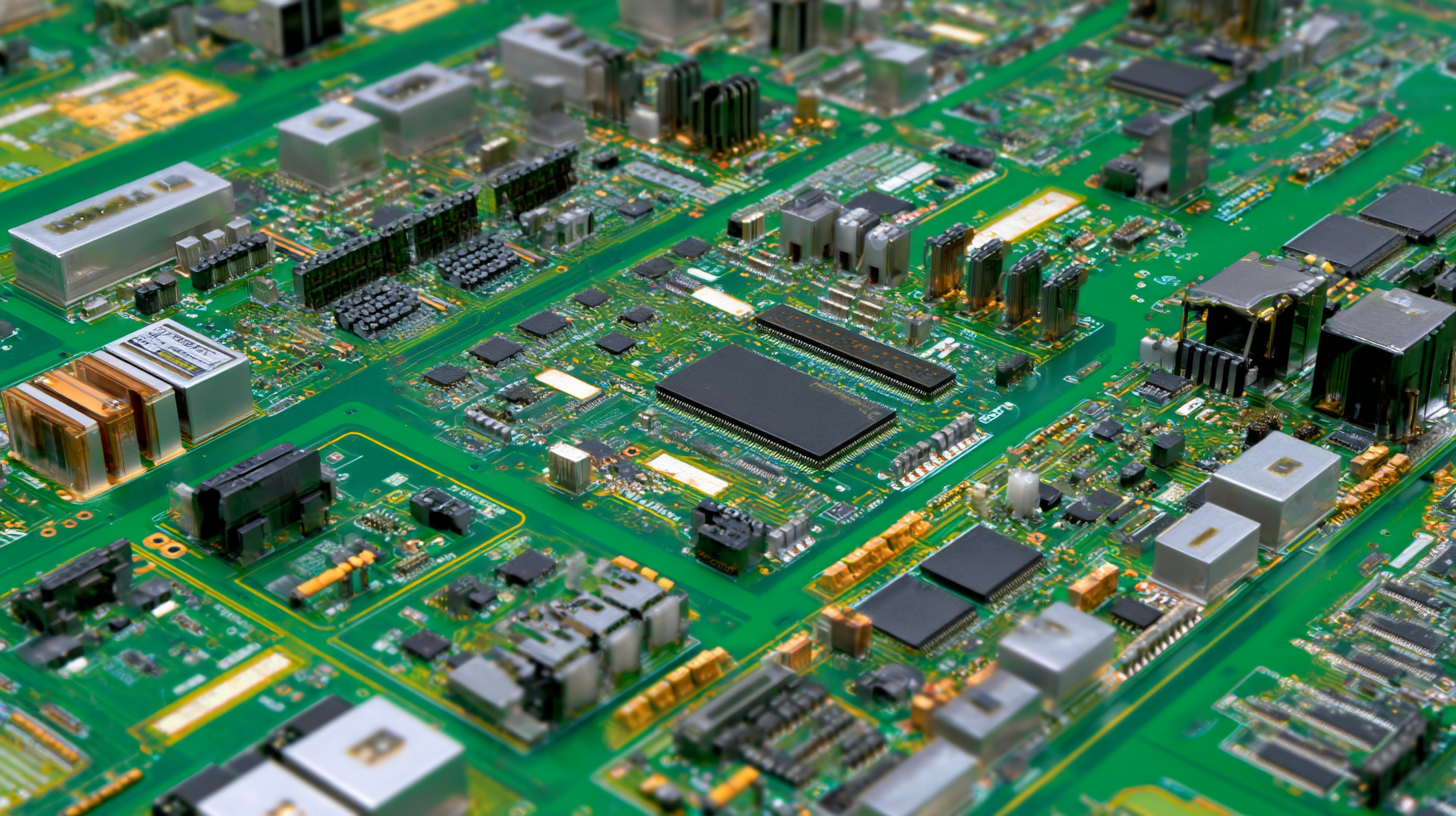

In the fast-paced world of printed circuit board (PCB) manufacturing, achieving efficiency in production timelines is essential for global buyers. According to a report by IPC, a major industry association, 83% of manufacturers consider reducing lead times as a critical goal for maintaining competitive advantage. By implementing best practices, such as establishing clear communication channels and employing agile project management techniques, companies can significantly enhance their production efficiency.

Moreover, adopting automated processes and leveraging advanced technologies, like real-time monitoring and predictive analytics, can help identify potential bottlenecks before they impact timelines. A study by the Committee for Technological Advancement found that firms utilizing automation in their PCB production witnessed a 30% reduction in cycle times. This not only accelerates the production process but also ensures higher quality outputs, as greater control minimizes human error. By embracing these innovative practices, global buyers can ensure their PCB production timelines align with market demands while maintaining the highest standards of quality.

When embarking on PCB procurement, global buyers often encounter several common pitfalls that can compromise both quality and efficiency. One major issue is inadequate communication with manufacturers. Language barriers, cultural differences, and vague specifications can lead to misunderstandings, resulting in products that do not meet the buyer's expectations. To avoid this, it is crucial to establish clear communication protocols and provide detailed documentation of requirements, ensuring that all parties are on the same page.

Another common challenge is the failure to conduct thorough supplier evaluations. Many buyers may choose suppliers based solely on price, overlooking critical factors such as production capacity, quality control processes, and past performance. This can lead to delays and defects that undermine project timelines. To circumvent this issue, buyers should implement a structured evaluation process, including audits and assessments of the manufacturer's capabilities. By doing so, they can make informed decisions that align with their quality and efficiency goals, ultimately leading to a more successful procurement experience.

| Dimension | Details | Common Pitfalls | Avoidance Strategies |

|---|---|---|---|

| Supplier Selection | Choose suppliers with proven track records and quality certifications. | Overlooking supplier reviews and ratings. | Conduct thorough due diligence and reference checks. |

| Design Considerations | Ensure designs are manufacturable and adhere to specifications. | Inadequate communication of design requirements. | Utilize design reviews and pre-production samples. |

| Prototyping | Develop prototypes to validate design before mass production. | Skipping the prototype phase. | Always budget time for testing and iteration. |

| Quality Control | Implement rigorous quality assurance protocols. | Neglecting final inspection or testing. | Incorporate multiple verification stages during production. |

| Logistics | Plan for efficient shipping and delivery of components. | Unexpected delays due to poor logistics management. | Work with reliable logistics partners and track shipments. |

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division