In today's rapidly evolving industrial landscape, the demand for high-quality laser equipment has surged significantly, driven by advancements in technology and increasing application across various sectors. According to a report by MarketsandMarkets, the global laser cutting machine market is projected to reach $5.6 billion by 2025, growing at a CAGR of 6.9%. This trend underscores the critical role that laser equipment plays in enhancing manufacturing efficiency, precision, and productivity. Whether you are in the automotive, aerospace, or medical device industry, sourcing laser equipment that meets your specific business needs is essential for maintaining a competitive edge. This ultimate guide aims to provide you with in-depth insights and practical tips on how to navigate the complexities of sourcing high-quality laser equipment to ensure optimal performance and return on investment for your operations.

When sourcing high-quality laser equipment for various business needs, it is essential to understand the different types of lasers available and their applications across industries. For instance, fiber optic lasers (FOL) are commonly utilized in automotive and aerospace sectors due to their ability to deliver efficient and precise material processing solutions. The rising demand for accuracy in manufacturing has led to an increase in the adoption of these powerful tools, making them a vital consideration for businesses looking to enhance operational efficiency.

Another key player in the laser equipment market is the CO2 laser, known for its versatile applications in both industrial and medical fields. These lasers are predominantly used for cutting, engraving, and welding, proving invaluable in manufacturing settings. The growth of the medical sector has particularly fueled the advancement and demand for CO2 lasers, as they are employed in a range of treatments and procedures. Understanding these nuances in technology and applications not only helps businesses make informed decisions but also enables them to meet industry-specific requirements more effectively.

This chart illustrates the various types of laser equipment and their applications across different industries, highlighting the percentage of usage in each sector.

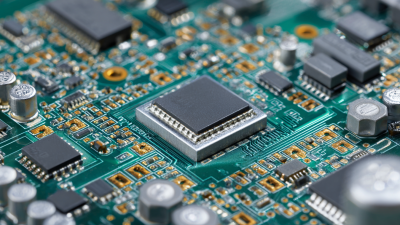

When sourcing high-quality laser equipment for your business needs, three key factors must be taken into account: quality, performance, and cost. According to a report by the Laser Institute of America, the global laser market is projected to reach $18 billion by 2025, highlighting the growing demand and the importance of selecting the right equipment. Ensuring the quality of your laser equipment is paramount, as a high-quality machine not only enhances precision but also minimizes long-term operational costs due to reduced downtime.

Performance directly impacts productivity. Equipment with advanced features like adjustable power settings and enhanced cooling systems tends to deliver superior cutting speed and accuracy, essential for industries such as manufacturing and medical applications. A study by IBISWorld shows that businesses investing in high-performance laser equipment can improve production efficiency by up to 30%.

Tip: When evaluating equipment, consider conducting hands-on demonstrations to assess performance firsthand. Additionally, always review warranty terms and manufacturer support to safeguard your investment. Cost, while crucial, shouldn't compromise the other factors; the right equipment should offer a balanced mix of affordability and performance to ensure a sustainable return on investment.

As industries continue to evolve, the demand for high-quality laser technology is escalating. The market for industrial welding robots, in particular, is experiencing significant growth. With segments such as spot welding, arc welding, and laser welding robots, businesses are realizing the benefits of automation in production processes. Applications in automotive, aerospace, and heavy machinery are driving this trend as companies seek to improve efficiency and minimize human error.

Tips for sourcing high-quality laser equipment include conducting thorough market research to understand the latest technologies available. Evaluate suppliers based on their reputation, customer feedback, and warranty offers. Don’t hesitate to inquire about the technological specifications—this can significantly impact your operational efficiency.

Additionally, pay attention to emerging trends such as the increased integration of laser cutting machines across various sectors. The laser cutting machine market, projected to grow significantly by 2032, presents opportunities for businesses willing to adapt to advanced manufacturing processes. As a tip, look for machines that offer flexibility in application and maintenance ease, as these factors can enhance your operational capabilities in the long run.

When it comes to sourcing high-quality laser equipment for your business, identifying and verifying reputable suppliers is crucial. Certified suppliers often provide assurance of the quality and reliability of their products. Start by seeking manufacturers that have industry certifications, such as ISO standards, which reflect their adherence to quality management systems. Additionally, look for suppliers who are members of recognized trade organizations, as this often indicates a commitment to maintaining high industry standards.

Once you have a shortlist of potential suppliers, conduct thorough research to assess their reputation. Online reviews, testimonials, and case studies can offer valuable insights into the experiences other businesses have had with these manufacturers. Don't hesitate to reach out to their existing customers for feedback. Moreover, consider visiting the supplier's facilities, if possible, to get a firsthand look at their operations and quality control processes. Engaging with suppliers directly can also help establish a relationship built on trust, which is fundamental when investing in high-quality laser equipment for your business needs.

| Supplier Criteria | Description | Certification Type | Country of Origin | Average Lead Time | Warranty Period |

|---|---|---|---|---|---|

| Production Capacity | Ability to meet large volume orders | ISO 9001 | USA | 4-6 weeks | 2 years |

| Customer Reviews | Positive feedback from industry clients | CE, RoHS | Germany | 3-5 weeks | 1 year |

| Technical Support | Availability of after-sales service | ISO 13485 | China | 6-8 weeks | 3 years |

| Pricing Structure | Transparent and competitive pricing | FDA Approval | Japan | 5-7 weeks | 2 years |

When it comes to implementing laser equipment in your business operations, maximizing ROI is essential. One key strategy is to thoroughly assess your specific needs before making a purchase. Consider the type of materials you’ll be working with and the scale of production required. This careful alignment of equipment capabilities with operational demands ensures that you’re investing in technology that will deliver the best performance and efficiency.

Tip: Conduct a cost-benefit analysis that includes not only the initial investment but also potential long-term savings. Analyze factors such as maintenance costs, energy consumption, and the expected lifespan of the equipment. By understanding these elements, you can make a more informed decision that aligns with your financial goals.

Additionally, consider integrating laser equipment with existing workflows. This can significantly reduce setup times and increase throughput. Training your team on best practices for using and maintaining the equipment is crucial as well. A well-trained staff can optimize productivity and minimize downtime, both of which are essential for maximizing your return on investment.

Tip: Develop a standard operating procedure (SOP) for the use of laser equipment. This not only helps maintain consistency in output but also ensures safety protocols are followed, ultimately contributing to a smoother operation and improved ROI.

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division